The third annual Accelerated Innovation in Manufacturing Biologics (AIM-Bio) Symposium, which took place Nov. 9–11, 2022, was the first symposium to be held in person. Due to the pandemic, previous meetings took place in an online virtual environment and, in 2021, with limited face-to-face events on the campuses of NC State and the Technical University of Denmark (DTU). As a result, symposium organizers were interested in providing ample opportunities for participants to network and meet in person during the 2022 symposium. Attendees had the opportunity to do just that during the campus-wide open house held on Nov. 10, the second day of the event.

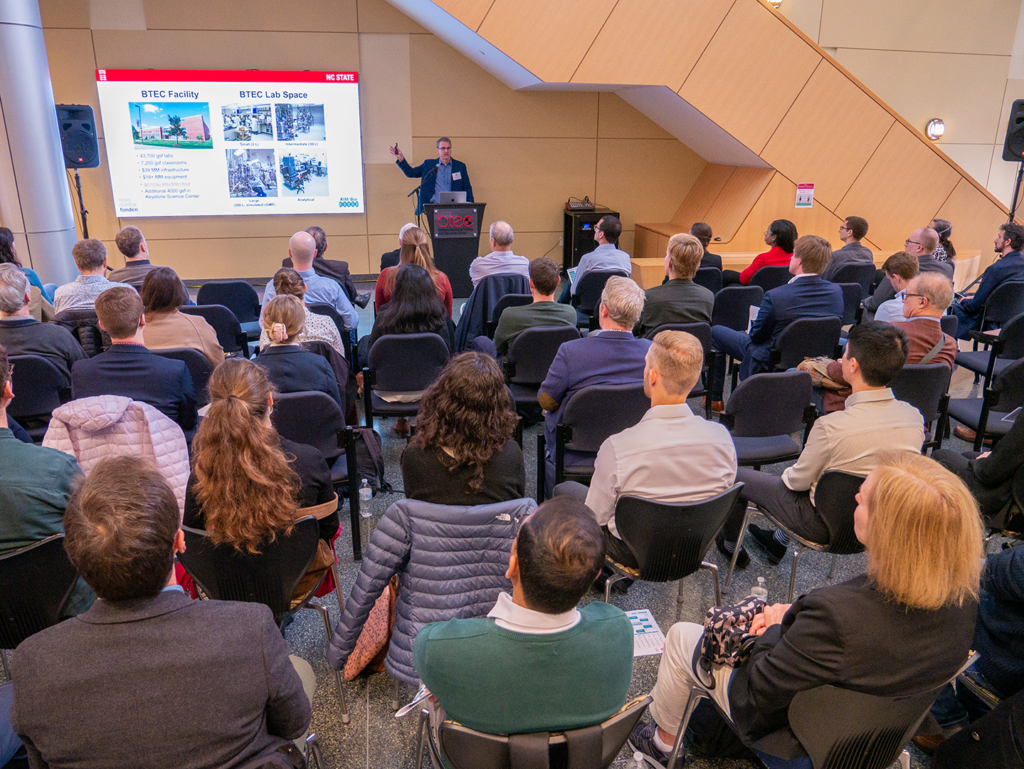

The open house began at NC State’s Biomanufacturing and Training Education Center (BTEC). The BTEC lobby was filled with posters highlighting eight new BTEC professional development courses and several courses transferred to DTU to help establish their new Biotech Lifelong Learning program. (The AIM-Bio program funded development of BTEC’s new courses and transfer of courses to DTU.)

Dr. Gary Gilleskie, BTEC’s executive director, opened the meeting with a presentation that described the history of the center and provided information about its academic and professional development programs. Then instructors described the AIM-Bio courses in a series of engaging one-minute lightning talks. The fast pace and energy of the lightning talks encouraged participants to view the course posters for more information.

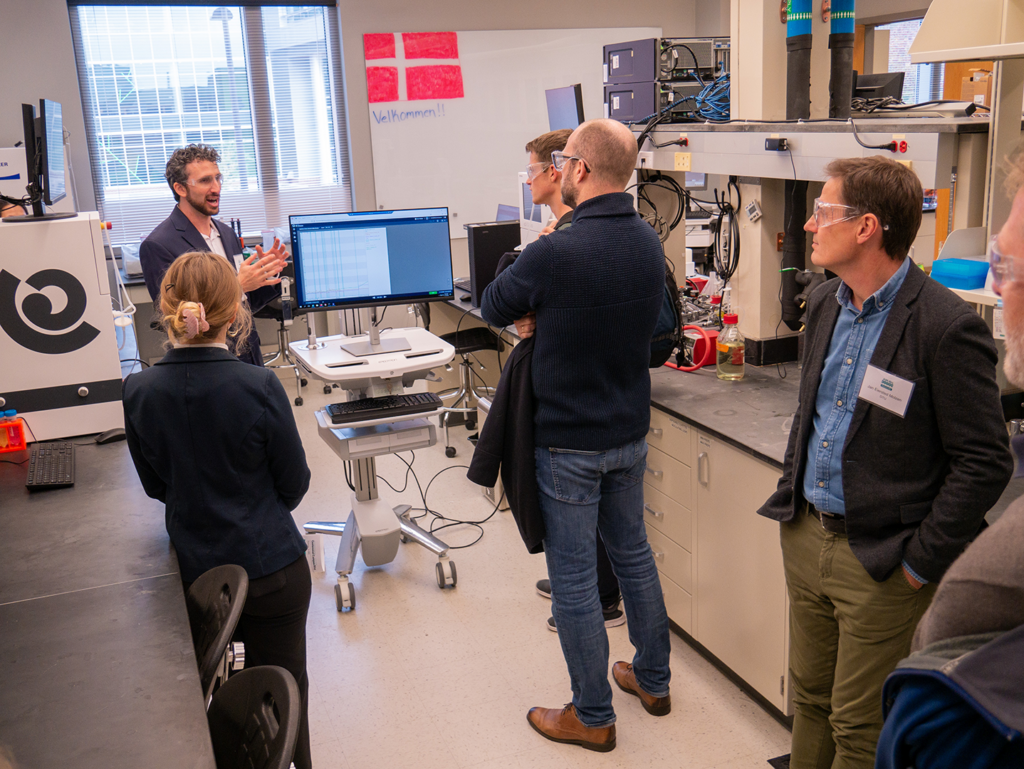

Next, visitors split into six different groups for a tour of the BTEC facility. The tour included the small, intermediate, and large scale simulated-cGMP labs along with focused review of equipment in the BTEC labs where the professional development courses are held.

Course overviews and equipment demonstrations were provided by:

- Dr. Ryan Barton, BTEC’s manager of Bioprocess Automation, for the Automation, Process Control and Real-time Monitoring of Yeast Culture course.

- Hunter Brown, a scientist at BTEC, for the Protein Precipitation/Crystallization course. (see photo below)

- Danny Schmitt, a scientist at BTEC, for the Analytical Methods for Gene Therapy Vector Characterization and Testing course.

- Scott Latus, BTEC’s educational communications programs manager, who presented information about online course development and technology.

The tours provided an excellent opportunity to showcase the BTEC facility, demonstrate equipment used in the new AIM-Bio courses, and highlight the instructional and technological expertise provided by the center.

In the afternoon, the guests were invited to visit the three research labs where the Single-Use Devices, Process Analytical Technologies and Cell Engineering research project teams are located. The groups met with the doctoral students on these teams and learned about their research projects.

All in all, the day provided multiple opportunities for discussion and enhanced collaboration to support the future of the program.