DTU and NC State delivered four AIM-Bio lifelong learning courses in March and April 2023. The 48 participants enrolled included 28 working professionals and 20 graduate students. A brief profile of each course follows.

Biopharmaceutical Lyophilization and Spray Drying

The Biopharmaceutical Lyophilization and Spray Drying course was held March 13–16 at NC State BTEC. Course lectures were delivered by Anthony Klos, who has over 30 years of experience with lyophilization in industry, and hands-on laboratory activities were facilitated by BTEC scientists Danny Schmitt, Sara Siegel, and Hunter Brown. The course provided participants the opportunity to learn the principles of lyophilization and spray drying, including heat and mass transfer, critical process parameters for cycle optimization, and the advantages and disadvantages of each technique. Laboratory activities included material characterization, freeze and spray drying runs, and final product testing. The seven participants reported 100% satisfaction with the course, and one commented, “The lab portions were great with an emphasis on what’s possible.”

Upstream Process Development

DTU was excited to deliver the Upstream Process Development course led by Dr. José Luis Martinez Ruiz, associate professor at DTU Bioengineering. The course, which took place March 27–31, attracted participants from companies such as Tetra Pak, LEO Pharma, and Norwegian Mycelium and included attendees from not only Denmark but also Sweden and Norway, making it an international learning experience.

Structured into three distinct modules — Biochemistry of Cell Growth and Physiology, Design of Experiments, and Scale-up, this comprehensive course aimed to equip participants with the necessary theory and skills to make informed decisions in upstream process development. With a particular focus on the application of design of experiments (DoE), attendees gained valuable insights into its use as a versatile tool, ranging from process development to production.

Biomanufacturing Operations and cGMP

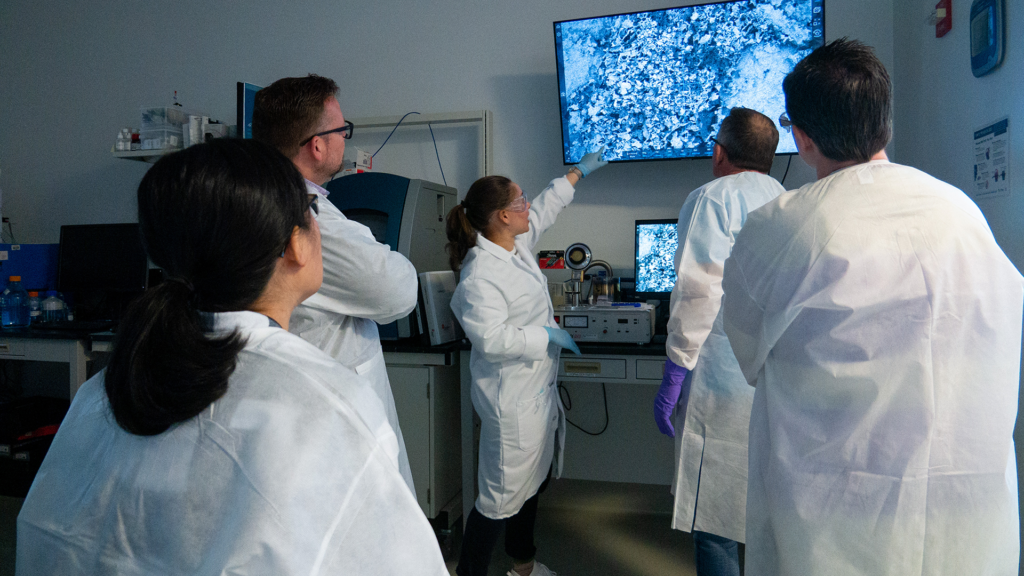

Tailored exclusively for FUJIFILM Diosynth Biotechnologies, the Biomanufacturing Operations and cGMP course was successfully delivered March 27–29 at DTU. Led by Dr. John Woodley, professor in the DTU Department of Chemical and Biochemical Engineering, the course provided participants with a comprehensive overview of the upstream and downstream operations integral to a successful biopharmaceutical process. With a strong emphasis on biopharmaceutical products and processes, orientation of experimentation and documentation, cell culture, and downstream, the course covered essential current cGMP requirements. It was an exciting opportunity for DTU to collaborate with the industry and design a customized course for the rapidly expanding Fujifilm, which is currently recruiting a significant number of professionals.

Participants appreciated the dynamics of the course, which struck an effective balance between hands-on cell culture and harvest techniques and theoretical lectures about biopharmaceutical manufacturing operations. Attendees’ feedback identified the course’s hands-on approach as a major strength.

Automation and Control of Yeast Fermentation

The Automation and Control of Yeast Fermentation course, held April 17–21 at DTU, provided participants with the necessary knowledge and skills to make informed decisions concerning on-line sensor selection for establishing closed-loop control in model fermentation processes, specifically focusing on yeast. Dr. Krist V. Gernaey, professor in DTU’s Department of Chemical and Biochemical Engineering, introduced participants to the theory of process control and provided instruction on using model simulations to study the impact of control strategies on bioreactors. The course also delved into on-line sensor concepts and taught participants how to work with on-line data, detect outliers, replace missing values, and classify data.

With participants from Denmark, Germany, and Sweden, the course attracted professionals from diverse backgrounds, including FMC and Insempra GmbH, as well as PhD students.