The three-day course Automation, Process Control and Real-time Monitoring of Yeast Culture was delivered at BTEC in March 2022. Utilizing the latest technology to teach advanced automation concepts to participants, this course includes both classroom and hands-on laboratory activities.

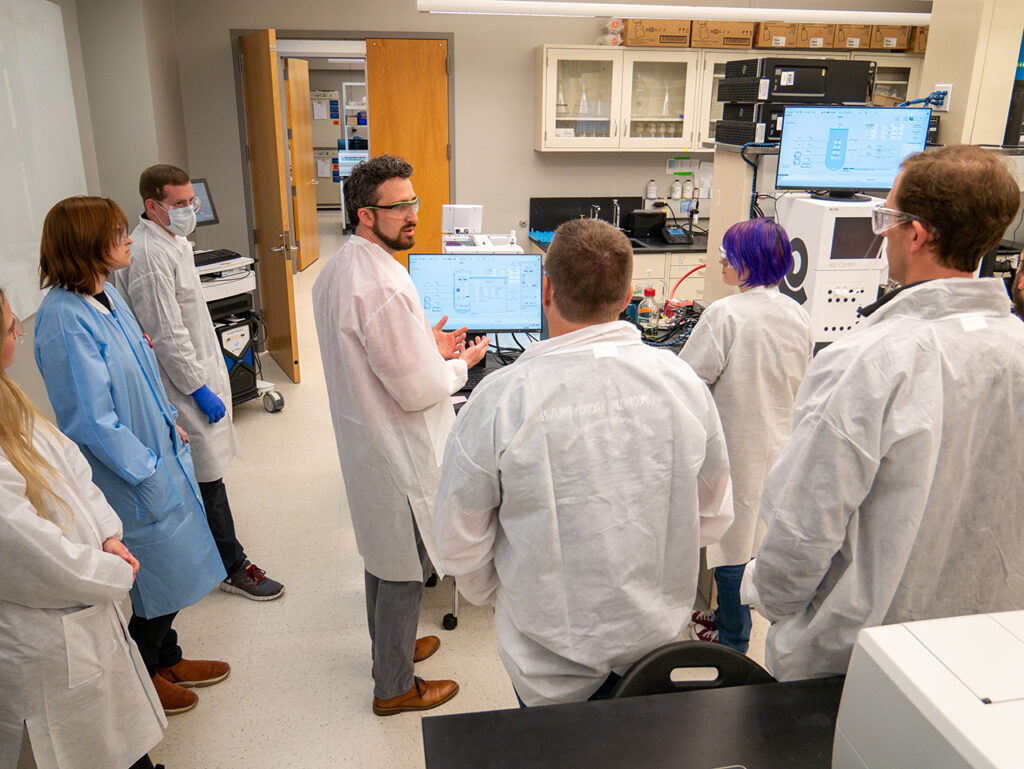

Ryan Barton, PhD, is describing split range control to maintain pH in bioreactors of yeast culture during the first offering of the Automation, Process Control, and Real-time Monitoring of Yeast Culture Course. Students, along with the instructors, Dr. Barton, Dr. Kurt Selle and Hunter Brown, AIM-Bio scientist, are setting tuning parameters and observing real-time functionality of the function block diagram for the various control modules associated with pH in DeltaV.

The Automation, Process Control and Real-time Monitoring of Yeast Culture Course is designed for scientists and engineers to gain familiarity with the functionality of control equipment and instrumentation. They also learn how rich datasets can be used to model yeast fermentation process parameters and enact near real-time feedback control to ensure a quality product. Dr. Ryan Barton developed the course with Dr. Kurt Selle and Hunter Brown who are all from BTEC.

The course utilizes new Applikon bioreactors to provide an introduction on how control modules use traditional sensors to monitor and control a process. The process data from the model yeast process is used to demonstrate the data communication and storage within a distributed control system (DeltaV DCS). This course builds on this data infrastructure to demonstrate the deployment of more advanced PAT sensors, such as Raman spectroscopy, to monitor process attributes normally not measurable in-line. Participants in the course gain hands-on experience with multivariate data analytics software to create these real-time predictive models and gain insight on how to use such a PAT for feedback control.

“Very passionate instructor with great knowledge on the subject”

From participant feedback

Seven participants attended the course, and course evaluations indicated that overall satisfaction was high. Participant feedback included the following comments: “Very passionate instructor with great knowledge on the subject” and “I really enjoyed the hands-on time with the software.”

This new AIM-Bio course is expected to be popular with industry participants seeking advanced knowledge and hands-on automation experience. The course team is looking forward to delivering the course again in July 2022 for eight participants, and course content will be enhanced for 2023 and beyond.